- Home

- FAQ Page

Wire Mesh FAQs

In this section, we provide insight regarding some of the most common inquiries covering topics such as different materials, which specifications to use, and how to choose the right products for specific applications. Please also feel free to contact us for further wire mesh information.

What are the different types of metal wire mesh and their uses?

Wire mesh can come in many forms and varieties depending on the material, construction, and specification of the product. The different types of wire mesh include woven, welded, perforated, and expanded. Each of these mesh products have unique constructions and applications that will aim to be explained in this section.

Woven wire mesh utilizes a loom to weave wires in an alternating pattern creating tension that holds the product together. There are no welds that hold the wires together in woven wire mesh as the loom creates a very tight pattern that prevents the wires from falling apart. Some of the larger, more open woven patterns that utilize thicker wires are often used in design applications including cabinetry, millwork, and railing infill. However, woven patterns can also get extremely fine, being able to filter out particles that are just a few microns wide. More specifically, our fine stainless steel woven products are often used for filtration purposes in the food industry, HVAC systems, and the medical industry. Woven wire mesh is often available in rolls, however some of our larger, more rigid patterns are only available in panels.

Welded wire mesh utilizes weld points at the intersection between two wires to hold the material together. Welded wire mesh is a cost effective option with high tensile strength and is often used for the reinforcement of concrete in the construction industry. Welded wire mesh is also available in rolls and panels depending on the specifications. Much like weavemesh, the thicker-gauge welded specs are only available in panels while lighter gauges are available in rolls. Welded wire mesh is also commonly used for outdoor railing applications especially for wildlife control due to its strength. More specifically, black PVC coated weldmesh and galvanized weldmesh are known for being able to withstand harsh outdoor environments as they are not as susceptible to rust or corrosion as other materials.

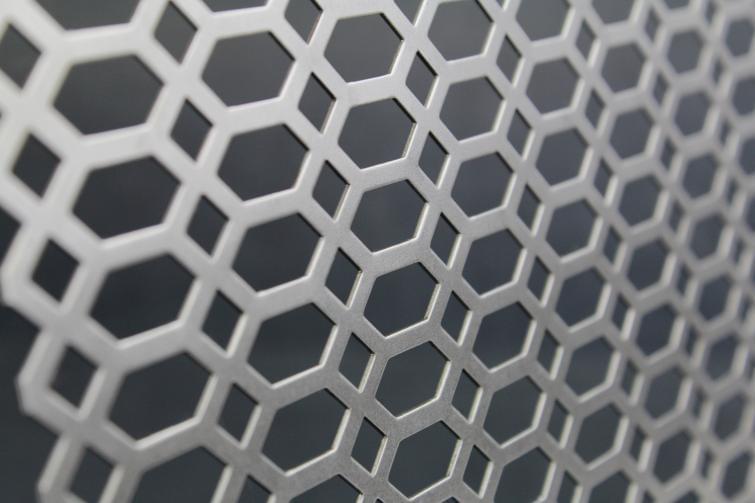

Perforated metal refers to sheet metal that has been punched by precise CNC tooling, allowing open area patterns to be punched into sheets of metal. Ferrier Wire stocks two distinct types of perforated metal; design perforated and round hole perforated. Both of these products are commonly used in design applications such as millwork, railing infill, ceiling tiles, and privacy screening. Perforated metal provides a cost effective option relative to other materials and provides the ability to distribute weight. It is worth noting that most of our design perforated products are made from mild steel sheets meaning that they will slowly rust over time if left unfinished. Ferrier Wire does offer metal finishing options and powder coating that will prevent mild steel from rusting, for more information feel free to contact us.

Expanded metal is made from first making multiple slits in a solid piece of sheet metal, then specialized tooling is inserted into the slits and pulls them apart creating openings in the sheet metal that are often diamond shaped. Similarly to perforated metal, Ferrier Wire stocks two lines of expanded; design expanded (or design ampliato) and industrial expanded. These expanded products are often used as ceiling tiles, safety barriers, railing infill, and decorative facades.

For more information on any of our products or our finishing options, please feel free to contact us.

What coatings or finishes can prevent wire mesh from rusting?

Our Karo weavemesh with Lammin Kupfer plating.

When it comes to rust, metals such as mild steel are at high risk because they contain high amounts of iron. When iron is exposed to oxygen, over time a chemical reaction occurs causing oxidation and rust. Some ways to combat rust in metals are wax, oils such as WD-40,or lacquer which can block oxygen and water from reacting with the metal. Additionally, more decorative options such as paint or powder coating can be utilized to protect metals from oxidization. Ferrier Wire offers a wide variety of powder coating and plating options that will help protect metals from rust. Powder coating is a unique electrostatic process where a positively charged finish is sprayed onto the material which is negatively charged. This offers a cost-effective finishing option with minimal powder waste. Alternatively, Ferrier Wire also offers plated finishes which is a more labour intensive, expensive option but offers unique finishes that offer excellent rust protection. For more information on our powder coating and finishing options please feel free to contact us.

What is the difference between plating and powder coating?

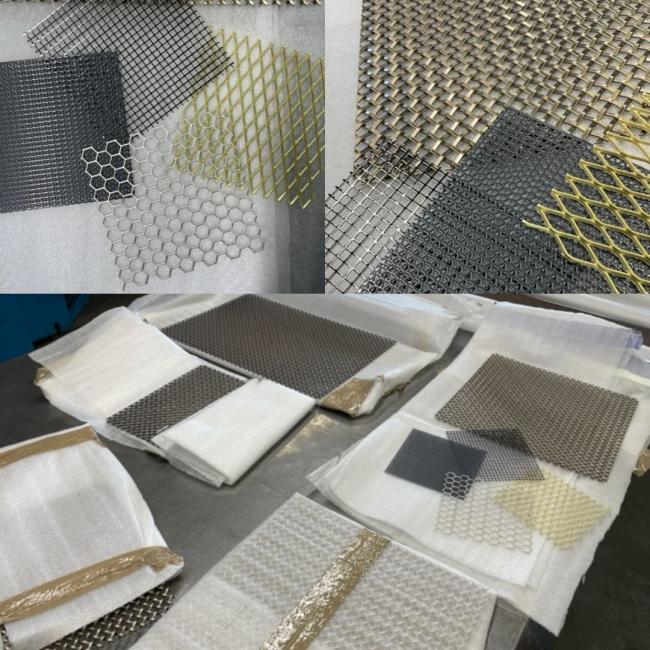

Some of the finishes offered by Ferrier Wire.

Powder coating and plating both present viable finishing options for materials such as mild steel, stainless steel, and aluminum. These finishes primarily aid in protecting material against corrosion and oxidization in harsh environments while also giving products unique appearances. The main difference between plating and powder coating is that while powder coating is a dry process where powder is sprayed onto the material via an electrostatic process, plating is a wet process where material is dipped into an electrolytic solution and metal ions are bonded to the material via a current being passed through the solution. Both of these processes create an even coating on the material that is chemically bonded to the material using charges between the coating and the material itself. Powder coating is more cost effective and less wasteful than plating however plating is able to offer a very smooth, even coating that offers a reflective and clean finish. Ferrier Wire is able to offer both powder coating and plating options for most of our materials, however we do not typically stock finished material. If you have any questions about finishing options for Ferrier products please contact us.

What is the difference between welded wire mesh and woven wire mesh?

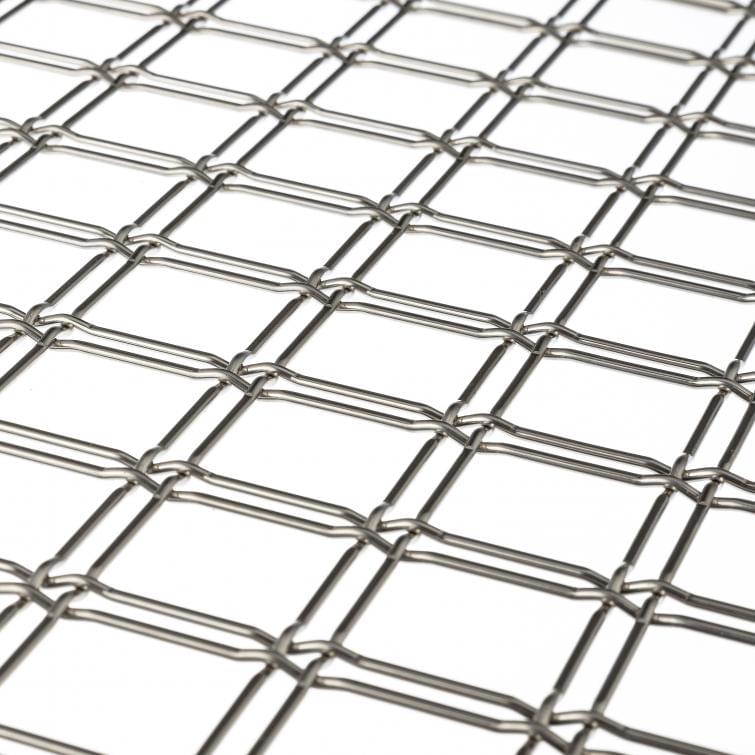

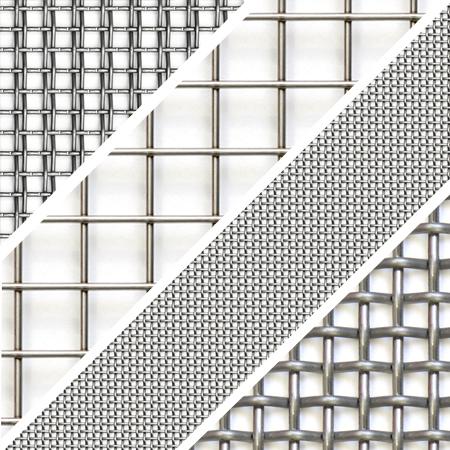

Some of our stainless steel welded and woven mesh.

Woven wire mesh utilizes a specialized loom that weaves wires in an over-under pattern, creating tension that holds the mesh together. For some larger woven mesh patterns, the wire is crimped (meaning there is a knuckle or bump in the wire) which helps keep the wires in place. Many of our design weavemesh patterns as well as some larger woven patterns are woven directly in house utilizing our own loom. Ferrier Wire stocks woven mesh in both 304 and 316 grade stainless steel, mild steel, brass, bronze, copper, galvanized steel, and aluminum.

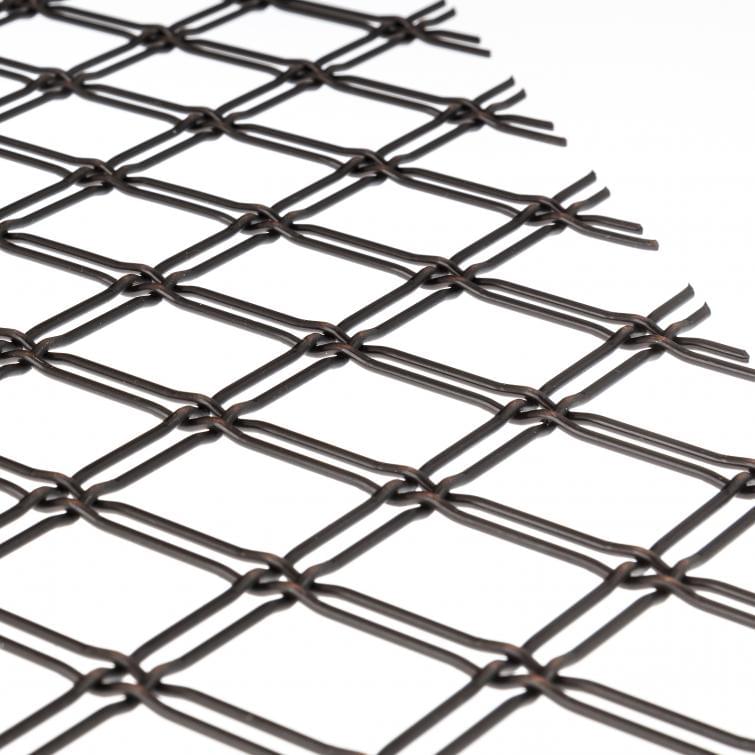

Welded wire mesh utilizes either MIG welding or spot welding in order to keep the wires in place. Welded wire mesh is often used in concrete and generally has much thicker wire diameters than those found in woven mesh. Ferrier Wire stocks welded wire mesh in 304 stainless steel, galvanized (zinc coated) steel, black PVC coated steel, and mild steel.

Which metals are best for outdoor wire mesh applications?

Our Black PVC weldmesh being used as a wildlife barrier.

When it comes to protection against the elements, typically black PVC coated mesh or galvanized material offer the most protection and resistance to corrosion. Ferrier Wires black PVC material is made from regular galvanized before welding (GBW) weldmesh that is then then dipped in a protective polyvinyl chloride coating creating a durable, corrosion resistant product commonly used for railings, playgrounds, marine applications, and other outdoor applications. Looking at some of Ferrier Wires other products, our galvanized after welding (GAW) selection also stands out for outdoor applications. GAW products are an electro-welded mesh that is then galvanized in a protective zinc coating after the welding process is already completed. This mesh is perfect for outdoor uses because unlike material that is galvanized before welding, GAW material weld points are protected from the elements by the zinc coating, offering more protection against corrosion. Some common applications for GAW material include outdoor fencing, cage mesh, and birdscreen.

How is decorative metal mesh used in architecture and interior design?

Our 1/2″ x 3/4″ Diamond perforated pattern at the ACC.

Decorative metal mesh patterns are commonly used in cabinetry, railing infills, ceiling tiles, and various other decorative accents. Ferrier Wire stocks many varieties of design weavemesh, expanded, and perforated decorative options. Wire mesh provides a very effective solution to both interior and exterior decor because it allows varying degrees of visibility with unique woven and perforated patterns without compromising the strength or integrity of a project. In addition to or design woven mesh, Ferrier Wire also stocks a wide variety of perforated metal sheets with decorative patterns punched directly through the metal. With the addition of our CNC Punching turret, we are able to punch our own custom perforated patterns that are perfect for decorative purposes. Perforated metal offers a cost effective, durable solution when it comes to decorative panels and privacy screens.

How is stainless steel mesh manufactured?

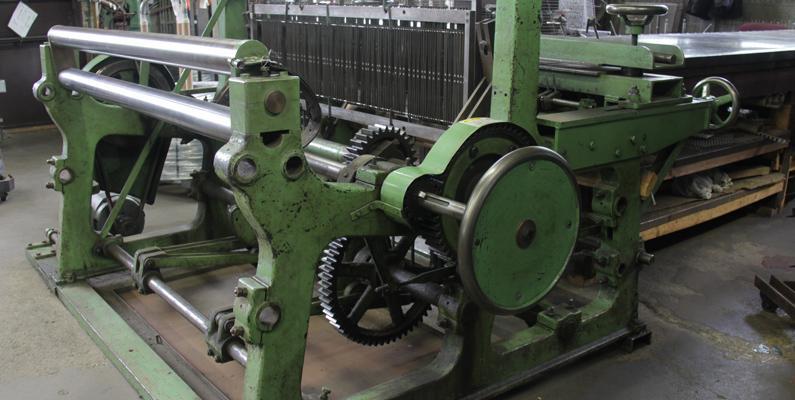

Our in house loom used for weaving.

Stainless steel mesh can be manufactured in one of two ways: it can either be welded or woven. When stainless steel mesh is woven, a specialized loom is used in order to weave the wires in a very tight over-under pattern, creating large amounts of tension to hold the mesh together forming sheets/rolls depending on the thickness of the wire used. Woven stainless mesh can be used for filtration, ventilation, sifting, and even some design applications. Alternatively, stainless steel mesh can also be welded utilizing either spot welding or MIG welding. In this process, the wires are joined together via welding and can come in many different wire diameters. Stainless steel welded wire mesh can be used for concrete mesh, guarding, and even straining for some smaller stainless welded mesh. Stainless steel mesh provides a great amount of tensile strength and corrosion resistance making this material perfect for structural support. In addition to this, the slick surface and corrosion resistance of stainless steel makes it very easy to clean and more difficult to contaminate, giving it many uses in the medical and food industries.

What is the difference between galvanized mesh and stainless steel mesh?

Our unique double-woven galvanized Doppio pattern.

The term galvanized mesh refers to mild steel mesh that has been hot dipped in a protective zinc coating that aids in protecting against corrosion in outdoor environments. Stainless steel is an alloy that consists of elements such as chromium, nickel, and iron, making it also extremely resistant to corrosion and rust, particularly our 316 grade stainless steel which is perfect for filtration and ventilation uses. The key difference is that galvanized mesh is referring to material coated in zinc, while stainless steel mesh refers to mesh that consists of stainless steel alloy. Common industries for stainless steel include the food, medical, and construction industries while galvanized material is often used for fencing, railings, and archeological sifting applications. Stainless steel is more expensive than galvanized material but it provides more longevity and strength than galvanized steel.

What are common applications for fine stainless steel mesh?

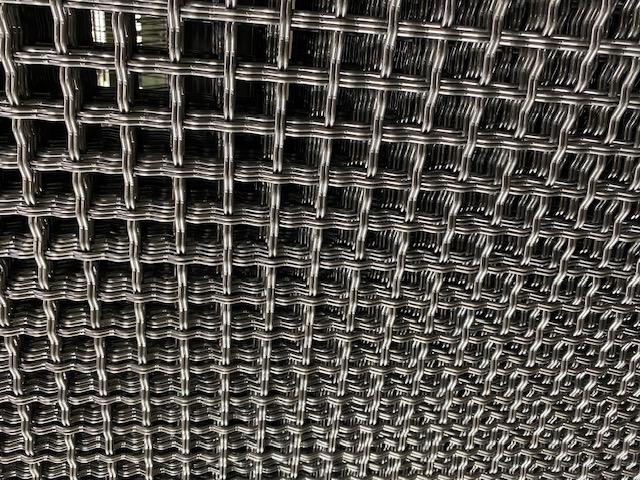

Some of our fine stainless steel mesh.

When looking at some of the finer stainless steel mesh counts such as 100 x 100 mesh – 500 x 500 mesh (100 holes per linear inch and 500 holes per linear inch respectively), these extremely fine meshes have applications in filtration, ventilation, and sifting. To give a real world example, Ferrier Wire supplies a Southern Ontario company with mesh filters used in ventilators in the medical industry. These extremely fine meshes are perfect for filtering out unwanted particles or objects. Specifications for all of our fine stainless products are also available in microns. Fine wire mesh is also used extensively in the medical industry for various tools and implants with its chemical structure making it resistant to rust and easy to clean. Fine stainless steel wire mesh also lends itself to the food industry specifically in the processing and refinement of foods.

We are here for you!

Whether you have questions, need details, or want support

for your project, we’re here to help!

170 Mulock Avenue Toronto, Ontario, M6N 3C8

Mon-Thurs 8:00 am - 4:00 pm Fri 8:00 am - noon

Shipping and receiving closed 12:30 pm - 1:00 pm

- Projects

- Gardiner Museum Renovation

- Air Canada Centre

- Spa privacy screen

- Sports and Country Bar

- Ottawa Art Gallery Railing

- Peter Powning's Light Spirals

- Black PVC Wildlife Barrier

- Union Station

- Aalto Grocery Store Signage

- Stoa Design Collective - Fleet's Foods

- Nightingale Restaurant

- Nathan Phillips Square

- Kelvin Kellman Architecture Boutique Shoe Salon

- Kilogram Studio Juice Bar

- Tennis Player

- Liz Pead

- Architect@Work

- Olena Kassian Sculpture

© 2026 Wire Mesh Supplier - ferrierwire.com. All Rights Reserved.

Powered by TechWyse

Stay up to date by subscribing to our newsletter.