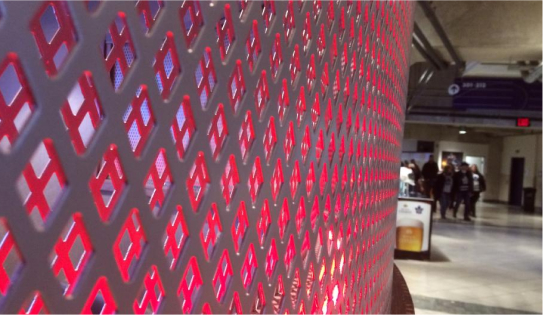

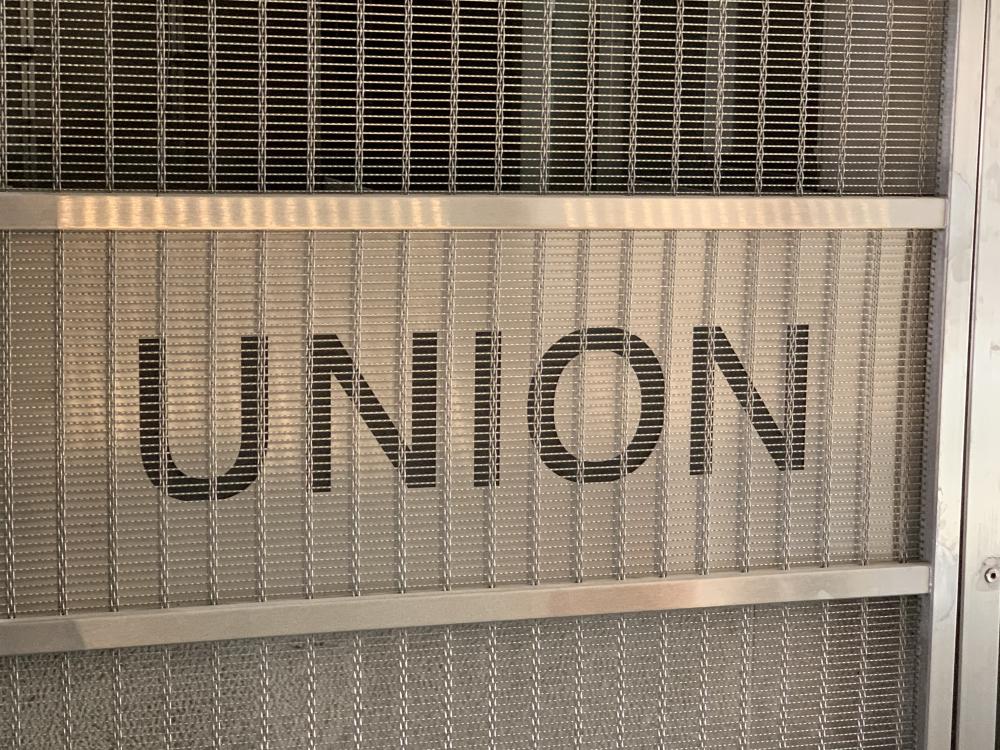

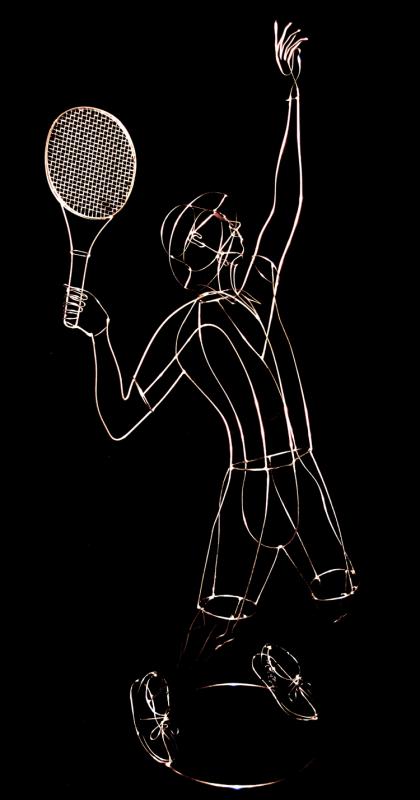

Industrial Expanded Metal

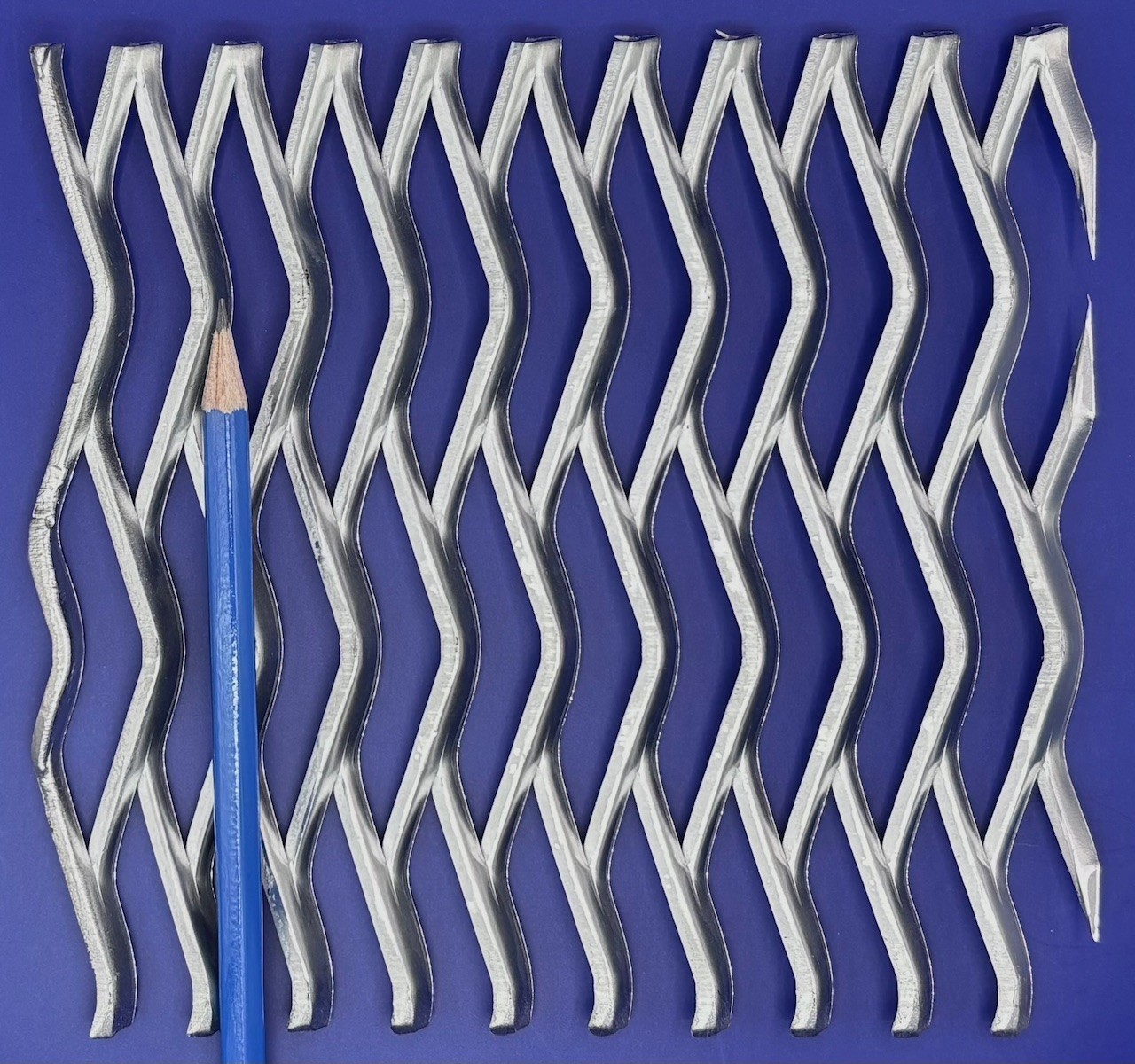

It is worth noting that due to the slitting and expanding process expanded metal may have sharp edges that must be handled with care. Oftentimes, the edges of expanded metal must be grinded down for safe handling. All of our expanded products can be powder coated or plated for a different finish, please feel free to contact us for finishing options. Unlike other product lines, expanded metal uses unique terminology to specify products. Some of the terms you may come across when dealing with expanded metal are as follows: SWO (Short way opening): the short way clear opening of the diamond LWO (Long way opening): the long way clear opening of the diamond SWD (Short way dimension): the short way dimension of diamond taken from center to center (not the same as SWO, this dimension is typically slightly larger) LWD (Long way dimension): the long way dimension of diamond taken from center to center (not the same as LWO, this dimension is typically slightly larger) For more information about our expanded products and their manufacturing process, please check out our product spotlight blog here. For more information about our range of Ampliato products, please email us.

Product Code : Ampliato AL Alto

Spec. Sheet

---Percent Open Area

52.00%Weight

85 lbs/csf (38.555 kgs/csf)Material

3003 H14 Almuinum Expanded MetalShort Way Opening

0.59" (14.986 mm) PITCHLong Way Opening

4.00" (101.600 mm) PITCH

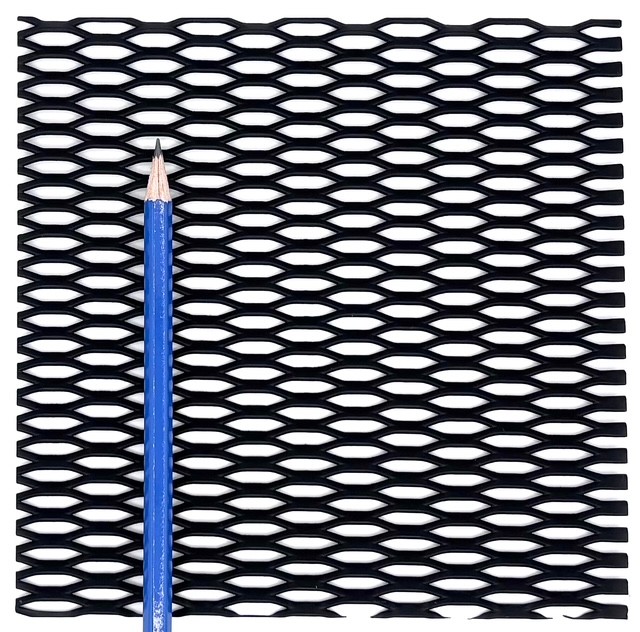

Product Code : Ampliato AL187032R

Spec. Sheet

Percent Open Area

52.00%Weight

28 lbs/csf (12.071 kgs/csf)Material

1100 H14 Aluminum Expanded MetalShort Way Opening

0.166" (4.216 mm)Long Way Opening

0.437" (11.010 mm)

Product Code : Ampliato AL500081F

Spec. Sheet

Percent Open Area

58.00%Weight

42 lbs/csf (19.051 kgs/csf)Material

3003 H14 Aluminum Expanded MetalShort Way Opening

0.312" (7.925 mm)Long Way Opening

1.000" (25.400 mm)

Product Code : Ampliato GALV7509F

Spec. Sheet

---Percent Open Area

N/AWeight

N/AMaterial

Hot Dip Galvanized Expanded MetalShort Way Opening

N/ALong Way Opening

N/A

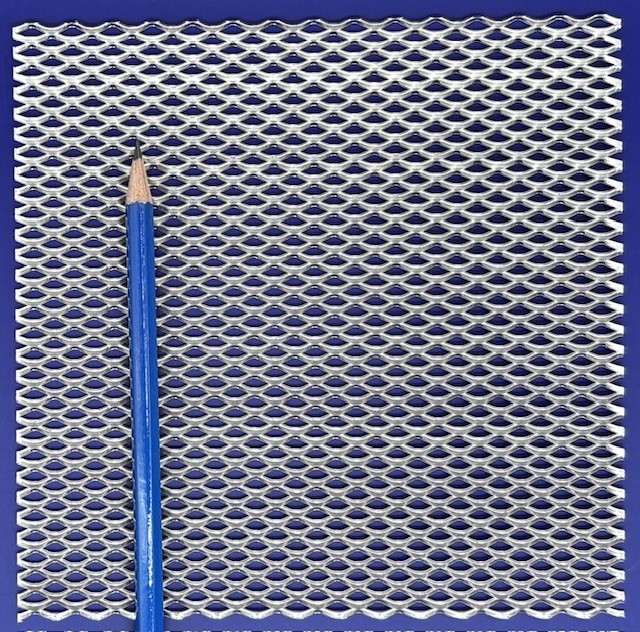

Product Code : Ampliato MSAPX3M13

Spec. Sheet

Percent Open Area

62.00%Weight

160 lbs/csf (72.575 kgs/csf)Material

Mild Steel (Unfinished) Expanded MetalShort Way Opening

~1.375" (34.925 mm)Long Way Opening

~4.750" (120.650 mm)

Product Code : Ampliato MS25018R

Spec. Sheet

Percent Open Area

43.00%Weight

114 lbs/csf (51.712 kgs/csf)Material

Mild Steel (Unfinished) Expanded MetalShort Way Opening

0.110" (2.794 mm)Long Way Opening

0.718" (18.237 mm)

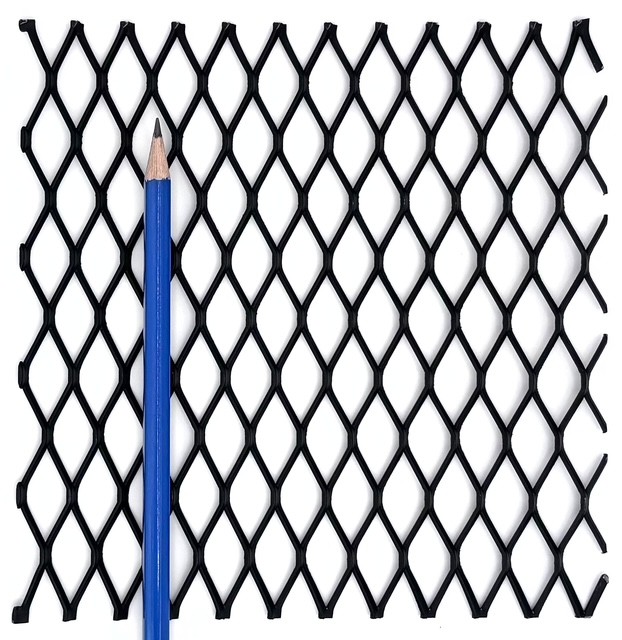

Product Code : Ampliato MS50018R

Spec. Sheet

Percent Open Area

72.00%Weight

70 lbs/csf (31.751 kgs/csf)Material

Mild Steel (Unfinished) Expanded MetalShort Way Opening

0.438" (11.125 mm)Long Way Opening

0.938" (23.825 mm)

Product Code : Ampliato MS50016F

Spec. Sheet

Percent Open Area

63.00%Weight

82 lbs/csf (37.195 kgs/csf)Material

Mild Steel (Unfinished) Expanded MetalShort Way Opening

0.312" (7.925 mm)Long Way Opening

1.000" (25.400 mm)Ferrier Wires line of industrial expanded (ampliato) metal products features expanded sheet metal available in aluminum, mild steel, and even stainless steel materials. The process for manufacturing industrial expanded metal is quite interesting and is comparable to the process of producing perforated metal. Much like perforated metal, raw material (in the form of either sheet metal or coils of metal) is fed into a press. The tooling in the press then comes down on the raw material, slitting it and then pulling it apart as the tooling is raised, this process is repeated throughout the material creating the desired expanded design. Due to the nature of the slitting and expanding process, the sheets or coils come out of the press in a curved manner and must be flattened with the use of rollers.

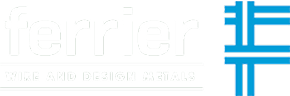

Industrial Expanded metal is available in 2 different varieties; raised (denoted by an “R” at the end of the pattern name) and flat (denoted by an “F” at the end of the pattern name). The difference between these 2 varieties lies with the edges of the material. Raised expanded metal does not have a flat surface and has raised edges that create a wavy texture on the material. Flattened expanded metal has a smooth texture on the face of the material and is the same thickness as the original raw material fed into the press.