- Home

- Industries

- Medical & Pharmaceutical

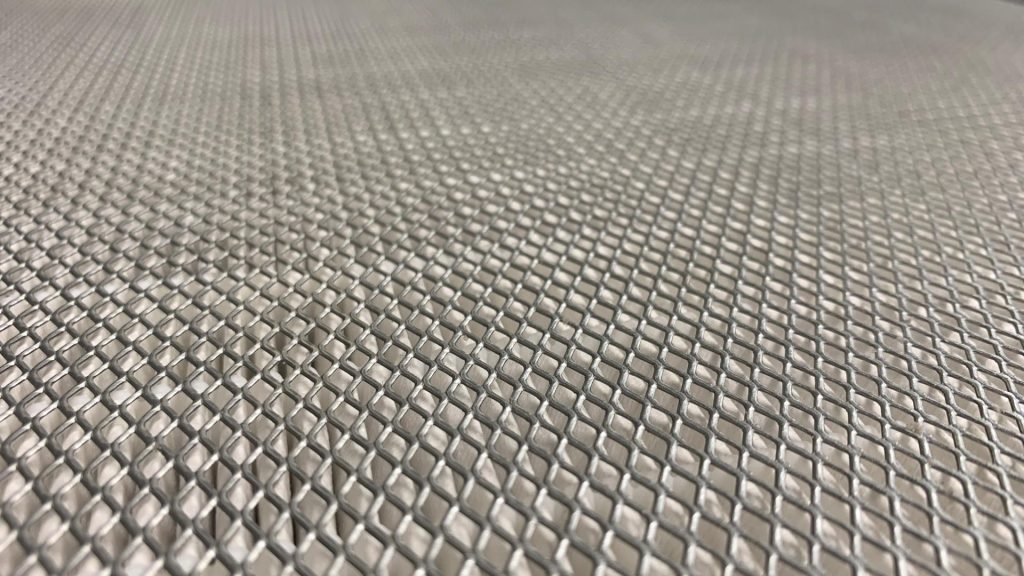

Wire Mesh in the Medical & Pharmaceutical Industry

Ferrier Wire supplies a wide range of wire mesh to meet the demands of the medical and pharmaceutical industries. Our products have a multitude of applications in these industries, including filtration, particle analysis, structural components for medical equipment and more. Often times our clients in the medical field must adhere to strict quality control standards used within the industry, forcing Ferrier Wire to take great care ensuring our products remain compliant with these regulations.

Ferrier Wire strives to supply wire mesh which meets the quality and precision requirements of our customers in the medical and pharmaceutical industries. Please contact us to see if we can offer a solution for your medical and pharmaceutical applications.

Applications in the Medical & Pharmaceutical Industry

Filtration Systems:

Wire mesh is regularly used in filtration systems in the medical and pharmaceutical industry, for example:

Intravenous Filters

IV filters utilize wire mesh to remove particles from fluids before they enter the bloodstream.

Blood Transfusion Filters

Wire mesh filters are incorporated into blood transfusion equipment to remove blood clots and other impurities from donated blood.

Sterile Air Vent Filters

In pharmaceutical production facilities, wire mesh is incorporated into the air vent filters to prevent contaminants from entering sterile production areas.

Equipment Screens:

Woven wire mesh is an essential component in protective screens for various machines and devices in the pharmaceutical industry. These equipment screens are integral to maintaining the purity and safety of pharmaceutical products.

Some applications of wire mesh products include:

- Filter out unwanted particles and contaminants during the tablet coating process

- Sieving and separating granules based on size

- Ensuring pharmaceutical powders are processed without foreign particles in milling and blending machines

- Serving as protective barriers to maintain quality in pharmaceutical packaging lines

Support Structures

Wire mesh is extensively used when creating support structures for medical devices and implants. Some specific applications include:

Orthopaedic Implants

Wire mesh is often used in joint replacements to provide a scaffold that promotes bone growth.

Vascular Stents

In vascular stents, woven wire mesh is used to create a flexible yet sturdy structure that can be expanded to open up narrow or blocked blood vessels. The mesh design helps the stent to conform to the vessel walls and provides strong support to maintain blood flow.

real world example

Looking at a real world example, Ferrier Wire works closely with a company located in Southern Ontario that specializes in ventilation, inhalation, and oxygen administration solutions within the medical field. Ferrier Wire supplies this client with custom-punched filters to be used in ventilation systems. These filters play a vital role in ensuring the delivery of safe, clean air to patients and essential workers. Before the pandemic, this company would typically order 5-600 filters per year. However, approximately three months into the pandemic Ferrier saw a 2,500% increase in filter orders when the company placed an order for 14,000 filters. Additionally, seeing as this customer provides potentially life-saving products, they have adopted the ISO 13485 quality standard for medical devices. With this quality standard in place, it is imperative that Ferrier Wire ensures these filters are fit to be used in medical devices no matter how large or small the order.

Choosing the Right Wire Mesh for Your Needs

Selecting the appropriate type of wire mesh is crucial for ensuring the safety, efficacy, and reliability of medical devices and pharmaceutical processes. Ferrier Wire is ready to assist you in choosing the right mesh for your specific application, ensuring compliance with the medical and pharmaceutical industries’ strict regulatory standards. Some of the most commonly used types of wire mesh in these industries include:

Stainless Steel

Stainless steel wire mesh is widely used in medical and pharmaceutical applications due to its excellent corrosion resistance, strength, and sterilizability. Type 316 stainless steel is preferred for its enhanced resistance to chlorides and acids, making it suitable for surgical instruments, implants, and filtration systems requiring frequent sterilization.

Titanium

Titanium wire mesh is highly valued in the medical field for its biocompatibility, lightweight nature, and high strength. It is used in dental and bone implants due to its ability to integrate well with bone and tissue, reducing the risk of rejection. Additionally, it is used in surgical tools that require repeated sterilization without compromising structural integrity.

Monel and Nickel Alloys

Monel and other nickel alloys are used in filtration systems requiring high corrosion resistance, especially in environments exposed to aggressive chemicals. They are suitable for pharmaceutical applications involving acidic or alkaline compounds, and are favoured for their high tensile strength and durability in demanding filtration and screening applications in the pharmaceutical industry.

Benefits of Using Wire Mesh in Medical & Pharmaceutical

Woven wire mesh is highly valued in the medical and pharmaceutical industries for its durability, hygiene, precision, and versatility. It can endure high pressure, temperature fluctuations, and frequent sterilization, ensuring long-lasting performance. Additionally, wire mesh can be manufactured to precise specifications often measured in microns, providing consistent performance in various medical applications.

Reach Out to Ferrier Wire Today

We offer customization options to tailor our wire mesh solutions to our clients’ precise needs. Whether you require a specific mesh size, material composition, or configuration, our team will work closely with you to create a customized solution that meets your exact specifications.

Ferrier Wire stocks a wide variety of 316 grade stainless woven wire mesh ranging from large welded panels to extremely fine specifications such as our 500 x 500 mesh with openings measuring just 25 microns. These extremely fine woven 316 products offer corrosion resistance as well as strong filtration capabilities making them ideal for various applications within the medical industry.

If you require wire mesh for medical or pharmaceutical applications, contact Ferrier Wire. Reach out to us today at 888-769-5280 or 647-799-3781 to find tailored solutions for your project needs.

We are here for you!

Whether you have questions, need details, or want support

for your project, we’re here to help!

170 Mulock Avenue Toronto, Ontario, M6N 3C8

Mon-Thurs 8:00 am - 4:00 pm Fri 8:00 am - noon

Shipping and receiving closed 12:30 pm - 1:00 pm

- Projects

- CF Toronto Eaton Centre

- Gardiner Museum Renovation

- Air Canada Centre

- Spa privacy screen

- Sports and Country Bar

- Ottawa Art Gallery Railing

- Peter Powning's Light Spirals

- Black PVC Wildlife Barrier

- Union Station

- Aalto Grocery Store Signage

- Stoa Design Collective - Fleet's Foods

- Nightingale Restaurant

- Nathan Phillips Square

- Kelvin Kellman Architecture Boutique Shoe Salon

- Kilogram Studio Juice Bar

- Tennis Player

- Liz Pead

- Architect@Work

© 2026 Wire Mesh Supplier - ferrierwire.com. All Rights Reserved.

Powered by TechWyse

Stay up to date by subscribing to our newsletter.