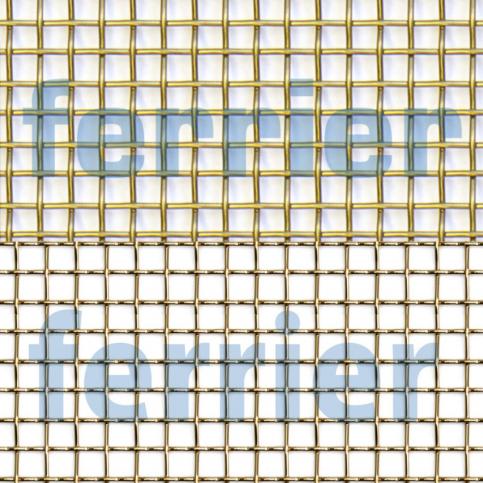

A wire mesh is made by weaving or welding two or more wires together to form a grid-like pattern. A variety of metals and alloys are used to make this mesh, including brass and bronze mesh. With copper being the base metal for both alloys, there are different characteristics for both these meshes. These differences will be examined below.

Differentiating Bronze and brass wire mesh

Bronze Mesh Composition:

Bronze is an alloy of copper and tin. Bronze embodies a lot of characteristics of copper, including its reddish hue. Hence, its mesh finds major uses as a decorative piece in cabinetry, jewelry, chandeliers, and more. Apart from this, it also has fundamental industrial and construction applications.

Brass Mesh Composition:

Brass mesh is composed of copper and zinc. The proportion of copper to zinc can vary, but it is typically around 60% copper and 40% zinc. This creates an alloy that is strong and durable with a relatively low melting point when compared to stainless steel. This makes it ideal for use in a variety of applications, especially as a wire mesh.

Comparison of a bronze and brass wire mesh

Corrosion Resistance

Bronze mesh is highly corrosion resistant and is also quite resistant to chemicals in general. In fact, it is superior to a brass mesh in this category. Therefore, it is widely used in many marine engineering applications apart from industrial and decorative purposes.

Strength And Malleability

Copper is known to be highly flexible and malleable. However, bronze is not as malleable as its base metal. It is also more brittle in nature than brass, which is known for its malleable properties. However, bronze is still fairly flexible.

Heat Resistance

When it comes to heat, both alloys are fairly equal. A bronze mesh can be considered slightly superior here, as it has a melting point of around 950 C (1742 F). Brass mesh, on the other hand, has a melting point of 900° C (1652° F).

Electrical Conductivity

Copper is considered the gold standard when it comes to electrical conductivity. Surprisingly, both bronze and brass mesh are not very good conductors despite being alloys of copper. However, brass is superior to bronze in this case, offering 28 percent conductivity, whereas bronze offers only 11 to 15 percent conductivity.

Therefore, these properties must be taken into consideration before selecting a bronze or brass mesh, as the two are not interchangeable in most situations.