- Home

- Knowledge

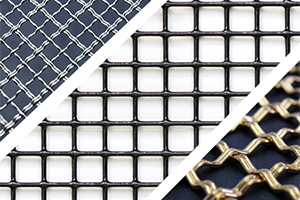

Wire Mesh Knowledge

To help you develop a good working knowledge of the various types of weavemesh (woven wire mesh), weldmesh (welded wire mesh), perforated metal and Ampliato (expanded) metal available on the market as well as understanding how the material is manufactured and specified. If you have any questions about the products, specifications or terminology, please contact us.

For more information about which Ferrier products might be right for you, please visit our FAQ Page.

Dutch weave

Strong fine filter cloth were the warp wires (long ones running parallel to the length) are thicker than the shute wires (short ones running across the width). There are fewer warp wires than shute wires. The shute wires actually touch each other and the opening through the mesh is not straight through (like regular plain weave mesh). The openings slant diagonally and are the little triangles where the shute wires run over and under the thicker warp wires.

Galvanized before welding (GBW)

The wire mesh is welded from a galvanized wire. This burns off the zinc coating at the weld and leaves a little dark mark at the weld. This material will start to rust at the welds if exposed to moisture. This product is usually less expensive than the GAW (see above).

LWD

An expanded metal term. Stands for long way diamond and is the opening of the long opening in expanded metal.

Centres

Commonly used to describe perforated metal hole spacing e.g. 1/4” dia holes x 3/8” staggered centres means the 1/4” dia holes are spaced 3/8” from the centre of one hole to the centre of the next hole. Determines the % open area i.e. the closer the holes are together the higher the % open area. When used to describe mesh, it is the distance from the centre of one wire to the centre of the next wire.

Percent open area

The percent open area in mesh and perforated relates to the amount of flow that will go through the mesh or perforated. The higher the percentage of open area, the more something will flow through the mesh or perforated. Another way to think about it is if a product has 40% open area, it means that 60% of that product is metal or solid. You can have mesh with small holes that has a larger percent open area than mesh with larger holes e.g. a 20 x 20 mesh x .016” dia wire has a .034” x .034” square clear opening with 46.2% open area and a 6 x 6 mesh x .062” dia wire has a .104” x .104” square clear opening (much larger holes) with a 38.9% open area (smaller open area).

Mathematically (for square mesh) it is mesh count squared multiplied by clear opening squared multiplied by 100 e.g. the percent opening of a 20 x 20 mesh x .016” dia wire is: 20^2 x .034^2 x 100 = 46.24% open area.

Plain weave

Weave mesh where wires simply run over and underneath each other.

Selvage

The finished woven wire mesh edge (running down the length). The wires loop back into the mesh i.e. the shutes are one continuous wire.

Staggered vs. straight centres

In perforated metal staggered holes are offset and usually in a 60 degree pattern. Straight line centres are all in line with each other, like a Pegboard pattern.

Clear opening

The actual opening or spacing from wire to wire, usually noted in inches or millimeters. Mathematically (for square mesh) it is (1/mesh count) minus the wire diameter e.g. the opening of a 20 x 20 mesh x .016” dia wire is: (1/20) – .016” = .034” x .034” square opening.

Twilled dutch weave

Same as dutch weave but the shute wires go over 2 warp wires and then under 2 warp wires allowing there to be more wires within a given area for even greater strength.

Warp

The wire running through the loom parallel to the length of the roll (long wires).

Galvanized after welding (GAW)

Welded mesh is made out of mild steel (plain steel) wire. The welded wire mesh is then hot dip galvanized in order to completely coat it. Galvanizing welded wire mesh after the welding process offers better corrosion resistance but is typically more expensive than GBW (see below).

Intercrimp or intermediate crimp

Extra crimp in wires between points of intersection (between wires). Usually only available on 1/2 x 1/2 mesh and coarser.

Market grade woven wire mesh

A family of mesh with heavier wire diameters than tensile bolting cloth for more strength and typically for industrial filtering applications.

Mesh or mesh count

The number of holes (not wires) per linear inch going across the width of the material x the number of holes per linear inch running down the length e.g. a 40 x 40 mesh has 40 holes per linear inch running across the width of the material and 40 holes per linear inch running down the length of the roll. Mesh is not always square e.g. flyscreen or window screen mesh count is 18 x 14 so the holes are actually rectangles. If a specification simply states 20 mesh, it is normally implied that it is a 20 x 20 mesh.

Micron rating

Microns are a very small unit of metric measure. 1 micron = .0000394 inches. Micron ratings are used to classify fine filter cloths, usually dutch weaves. Nominal and absolute micron ratings address how many particles of a certain size or larger will be restricted by a filter X% of the time. X is larger for absolute ratings than nominal ratings.

Reverse twilled dutch weave

Opposite of the dutch weave as there are more warp wires than shute wires and the warp wires are thinner than the shute wires. This results in the strongest filter weave mesh available.

Shute

The wire running across the width of the mesh (short wire). Also called weft or fill wire.

SWD

An expanded metal term. Stands for short way diamond and is the opening of the short opening in expanded metal.

Tensile bolting cloth

A family of woven wire mesh where the wire diameters are thinner than market grade wire diameters for larger percent open areas allowing for greater screen throughput.

Wire diameter

The diameter of the wire, usually noted in inches or millimeters. Certain families of mesh (hardware cloth, GBW, GAW, for example) specify wire diameters using gauge numbers e.g. 1/2 x 1/2 x 19 ga. Care must be taken when referring to gauges as there are many gauge standards and the corresponding diameters can vary by as much as 15-20%.

Crimp

Knuckles or bumps in the wire that keep the wires in position. When both warp and shute wires are crimped it is known as double crimp.

We are here for you!

Whether you have questions, need details, or want support

for your project, we’re here to help!

170 Mulock Avenue Toronto, Ontario, M6N 3C8

Mon-Thurs 8:00 am - 4:00 pm Fri 8:00 am - noon

Shipping and receiving closed 12:30 pm - 1:00 pm

- Projects

- Gardiner Museum Renovation

- Air Canada Centre

- Spa privacy screen

- Sports and Country Bar

- Ottawa Art Gallery Railing

- Peter Powning's Light Spirals

- Black PVC Wildlife Barrier

- Union Station

- Aalto Grocery Store Signage

- Stoa Design Collective - Fleet's Foods

- Nightingale Restaurant

- Nathan Phillips Square

- Kelvin Kellman Architecture Boutique Shoe Salon

- Kilogram Studio Juice Bar

- Tennis Player

- Liz Pead

- Architect@Work

- Olena Kassian Sculpture

© 2026 Wire Mesh Supplier - ferrierwire.com. All Rights Reserved.

Powered by TechWyse

Stay up to date by subscribing to our newsletter.