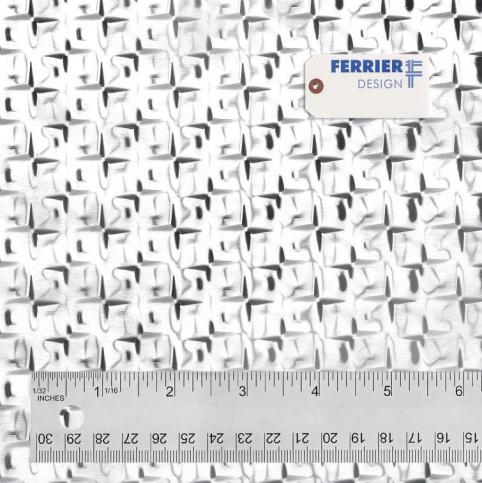

For aesthetic and utilitarian purposes, sheet metal is often given different textures. The design of the textured sheet metal mainly depends on how it will be used. One of the more common applications includes construction, where they are used to create doors, sidewalks, railings, walls and much more. To create these patterns, various techniques like hammering, rolling, heating and adding new raw materials to sheet metal surfaces are employed. These processes will be discussed below in detail.

Common methods of manufacturing textured sheet metal.

Hammering

As the name implies, hammering is a technique that uses hammers, either manually or automatically, to create stresses on the surface of the sheet metal, thereby creating unique textures. Depending on the required design, hammers of varying sizes are employed. Hammering is generally used to shape soft metals such as gold, silver, aluminium, copper and tin.

Rolling

Mostly an automated process, rolling involves the use of machinery known as rolling mills. While conventional rolling mills are used to reduce metal thickness and make it more uniform, in the context of creating texture on metal sheets, the mills have a unique design or indentation that can be imprinted onto the sheet metal. Highly optimized for speed, the only thing to consider in this process is the softness of the metal sheet, for it should be more elastic than the rolling mills themselves.

Heating

Heating is a versatile process wherein the heat can be used directly to create textures as well as add new, colourful designs on the sheet metal. Furthermore, since heating a metal makes it more malleable, it can be used in tandem with hammering or rolling to create the desired product. Some typical heating methods involve using a furnace, blowtorch or manual heat treatment.

Adding Raw Material

Unique textures can also be created by adding new raw material to the surface of the base metal. Some of the most well-known metal additives are welding wire, casting metal and plate metal. Apart from improving the aesthetics of the sheet metal, using a strong additive can also improve the overall strength and performance of the base metal.