Proven Success Stories

- Home

- Projects

See Craftsmanship OUR projects

A selection of projects which have incorporated Ferrier Wire + Design Metal Products. Please note that in most cases, we have supplied the material only, not the fabrication and installation services. If you have any questions about these projects or products, please email us.

-

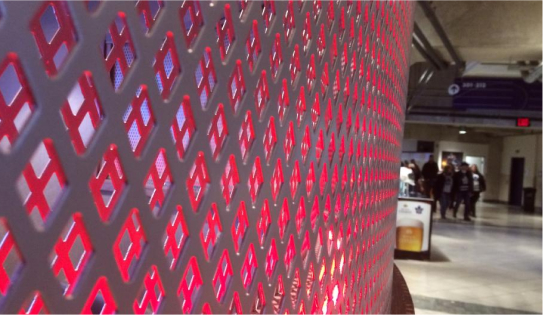

Air Canada Centreview project

Air Canada Centreview project -

Spa privacy screenview project

Spa privacy screenview project -

Sports and Country Barview project

Sports and Country Barview project -

Ottawa Art Gallery Railingview project

Ottawa Art Gallery Railingview project -

Peter Powning’s Light Spiralsview project

Peter Powning’s Light Spiralsview project -

Black PVC Wildlife Barrierview project

Black PVC Wildlife Barrierview project -

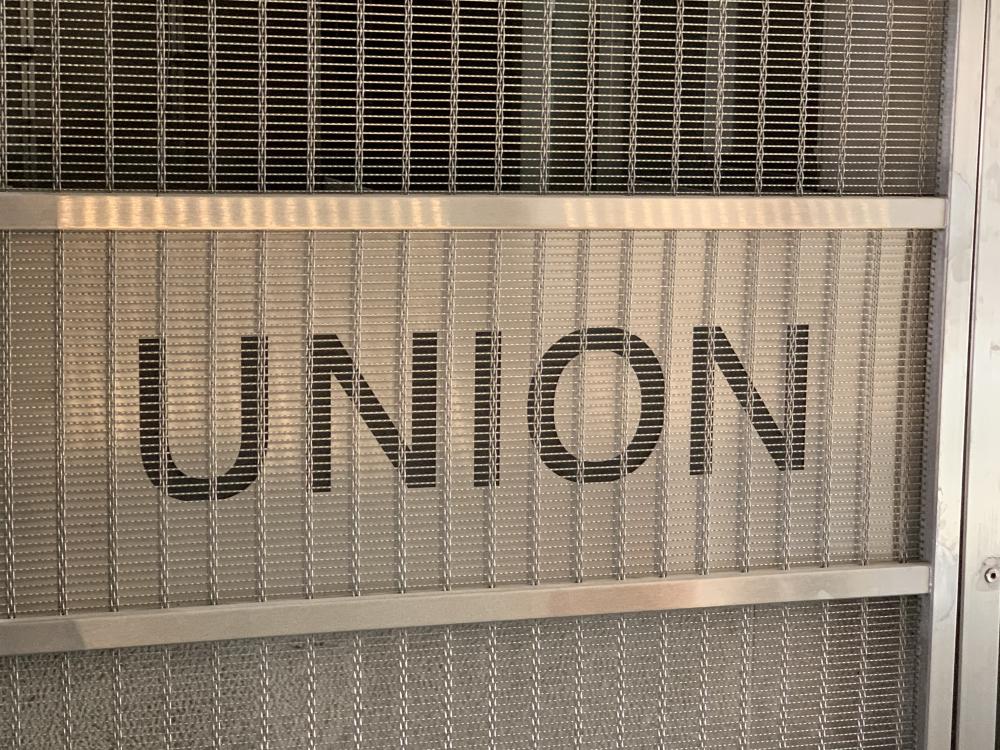

Union Stationview project

Union Stationview project -

Aalto Grocery Store Signageview project

Aalto Grocery Store Signageview project -

Stoa Design Collective – Fleet’s Foodsview project

Stoa Design Collective – Fleet’s Foodsview project -

Nightingale Restaurantview project

Nightingale Restaurantview project -

Nathan Phillips Squareview project

Nathan Phillips Squareview project -

Kelvin Kellman Architecture Boutique Shoe Salonview project

Kelvin Kellman Architecture Boutique Shoe Salonview project -

Kilogram Studio Juice Barview project

Kilogram Studio Juice Barview project -

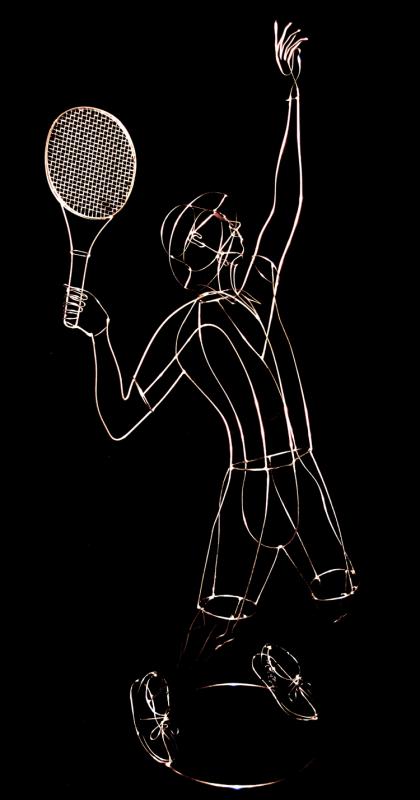

Tennis Playerview project

Tennis Playerview project -

Liz Peadview project

Liz Peadview project -

Architect@Workview project

Architect@Workview project -

Olena Kassian Sculptureview project

Olena Kassian Sculptureview project

Solutions for Performance & Creativity

Connect with Our Team & Kickstart Your

Project Today!

We are here for you!

Whether you have questions, need details, or want support

for your project, we’re here to help!

170 Mulock Avenue Toronto, Ontario, M6N 3C8

Business Hours:

Mon-Thurs 8:00 am - 4:00 pm Fri 8:00 am - noon

Shipping and receiving closed 12:30 pm - 1:00 pm

- Projects

- Air Canada Centre

- Spa privacy screen

- Sports and Country Bar

- Ottawa Art Gallery Railing

- Peter Powning's Light Spirals

- Black PVC Wildlife Barrier

- Union Station

- Aalto Grocery Store Signage

- Stoa Design Collective - Fleet's Foods

- Nightingale Restaurant

- Nathan Phillips Square

- Kelvin Kellman Architecture Boutique Shoe Salon

- Kilogram Studio Juice Bar

- Tennis Player

- Liz Pead

- Architect@Work

- Olena Kassian Sculpture

© 2025 Wire Mesh Supplier - ferrierwire.com. All Rights Reserved.

Powered by TechWyse

Ferrier Wire & Design Metals Newsletter

Stay up to date by subscribing to our newsletter.