In 2018, on Thursday October 11th during rush hour at Union Station, a chunk of concrete debris fell from above striking a woman in the head. Ferrier Wire was immediately contacted following the incident by a contractor working with Union station to make sure an incident like this could be prevented in the future. The contractor inquired if we had any mesh that could protect the public from falling debris. Ferrier Wire proposed a welded wire mesh GBW (Galvanized before welding) 1 x 1 x14 ga product. The product was approved for use at Union station and on Friday October 12th, Ferrier Wire delivered an order of this mesh directly to Union Station.

Fastforwarding to the Spring of 2022, Ferrier Wire was contacted again by a contractor looking for protective mesh to be used at Union Station. This time around, Ferrier Wire proposed a different welded wire mesh GAW (Galvanized after welding) ¾ x ¾ x 17 ga material. During discussions with the contractors engineering staff, a set of parameters were developed to test the material. The parameters established were as follows:

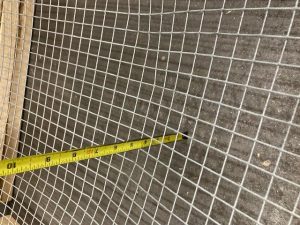

Material to be tested: GAW (galvanized after welding) ¾ x ¾ x 17 ga

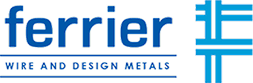

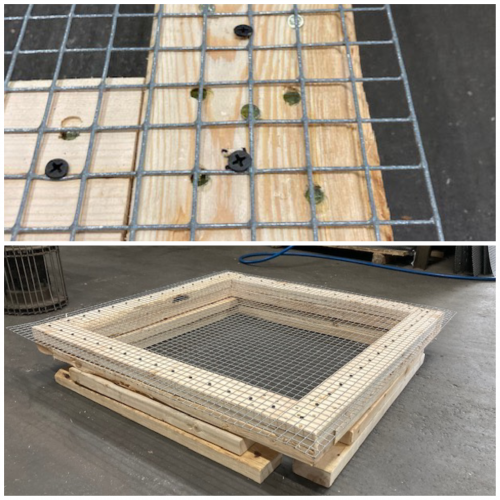

Method: Frame constructed from 2” x 4” lumber with a 30” x 30” clear opening

Mesh attached to frame with 1-1/4” black drywall screws every 3 holes around the perimeter

50+ lbs dropped from a height of no less than 600 mm (actual: 67 lbs from 685 mm)

Click here to view the video of the test.

Results and findings:

Mesh deformation of 57 mm (165 mm – 108 mm)

Mesh did not break anywhere at or around impact point

Several broken wires around perimeter where stress was maximum at the screws

Notes:

The use of the wooden frame and method of attaching the mesh to the frame was for test purposes only and does not reflect the actual installation method to be used on this project. The results noted above were what we expected and confirms that the weakest link in this specific design is the method of installing the mesh. We believe the use of a wire cable sufficiently supported and woven through the mesh would be a superior installation method.

This test was designed, documented and executed by Michael Wiebeck. Please note that I am not an engineer and created this test based on knowledge learned witnessing previous mesh tests.

As a result of the successful test, this material was approved for use at Union Station in the fall of 2022. Please contact us if you have any questions about this product or project.