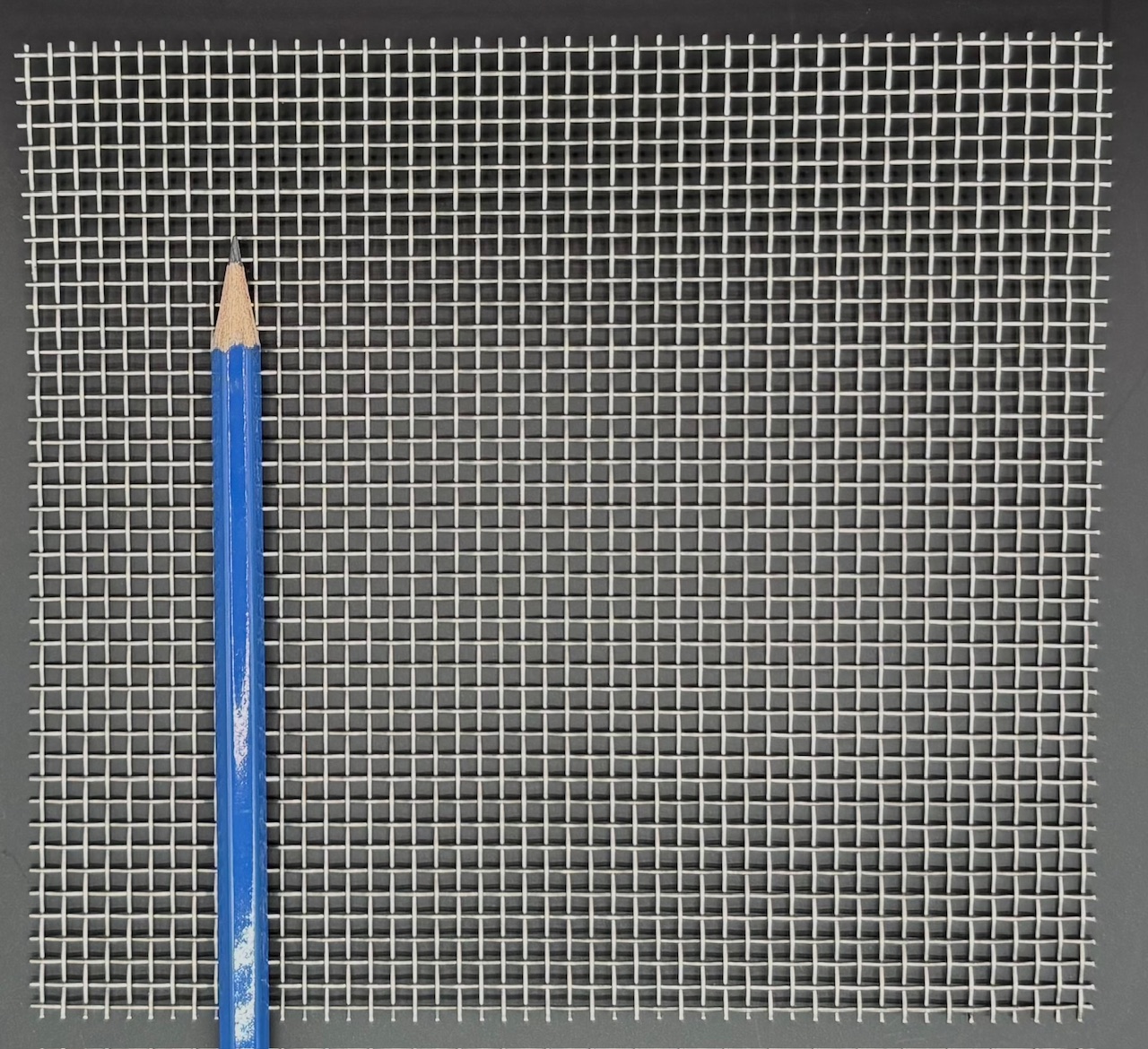

Aluminum weavemesh

Aluminum Weavemesh/Woven Wire Mesh

Aluminum woven wire mesh is made by weaving wire together on a weaving loom much like fabric is woven. Aluminum woven wire mesh is lightweight, corrosion-resistant and cost-effective when compared to stainless steel. Our 2” x 2”, 1-½” x 1-½”, 1” x 1”, ¾” x ¾” and ½” x ½” patterns are woven in-house and are stocked as 4’ x 8’ sheets. We offer custom widths and lengths, please inquire. Our in-house woven patterns are a pre-crimp wire mesh meaning that the wires are crimped before weaving. This helps keep the spacing consistent and reduces the chances that the wires can shift or be moved. The long wires (warp) are crimped and fed into the loom. The cross wires (fill) are also crimped and then fed into the loom which pushes them into place and advances the mesh. We have the capability to custom weave patterns as well. Our finer aluminum mesh (2 x 2 mesh - 18 x 16 mesh) are cut from rolls and are available in custom lengths. The roll widths and sizes can be seen below under the Roll width(s)/size column.

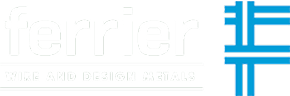

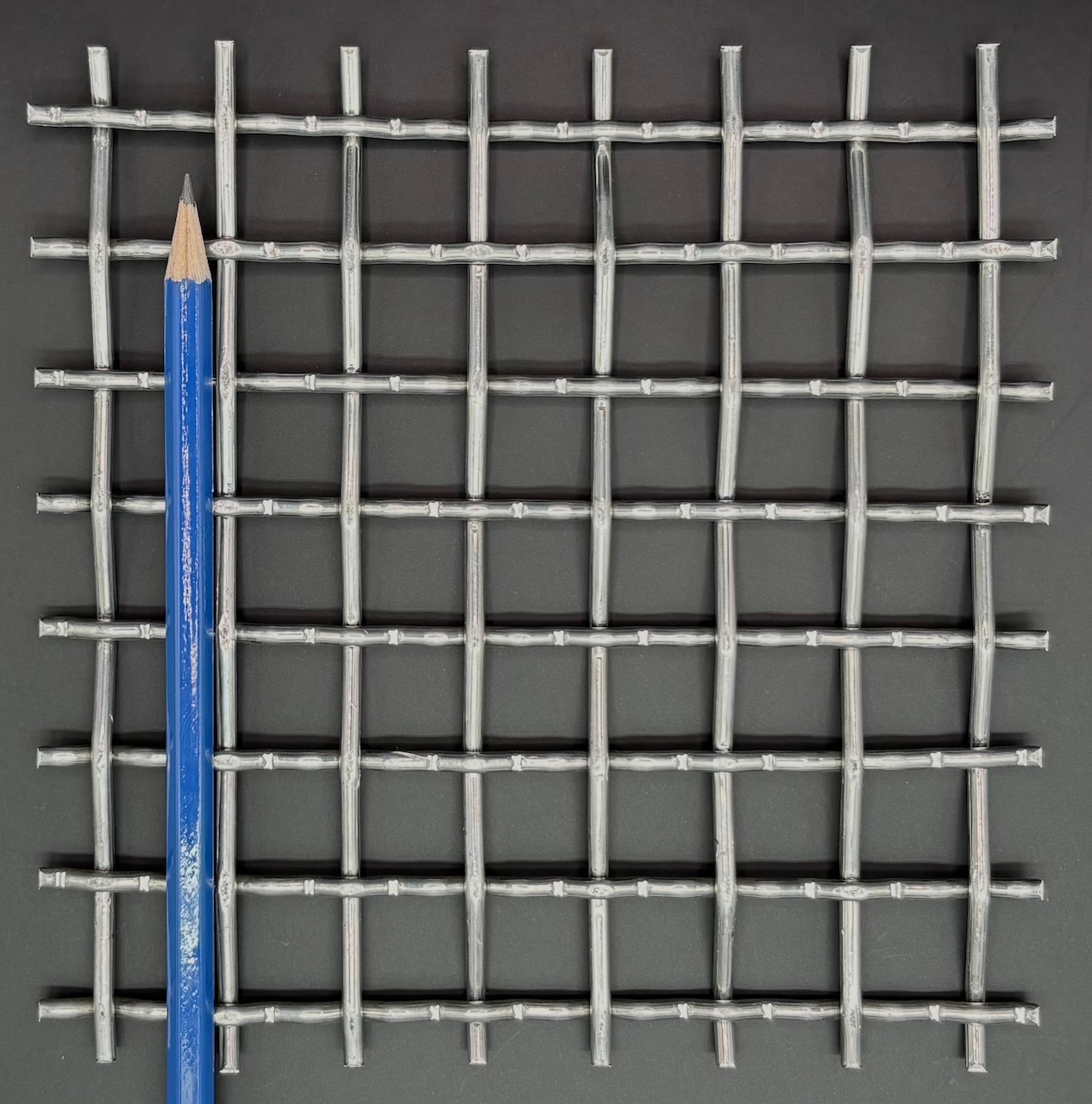

Product Code : ALWEA2I2I1875

Spec. Sheet

Centres or Mesh Count

2" x 2" (50.8 mm x 50.8 mm) c to cWire Diameter

0.1875" (4.76 mm)Clear Opening

1.875" (47.625 mm)Percent Open Area

87.90%Weight

0.40 lbs/sf (0.017 kgs/sf)

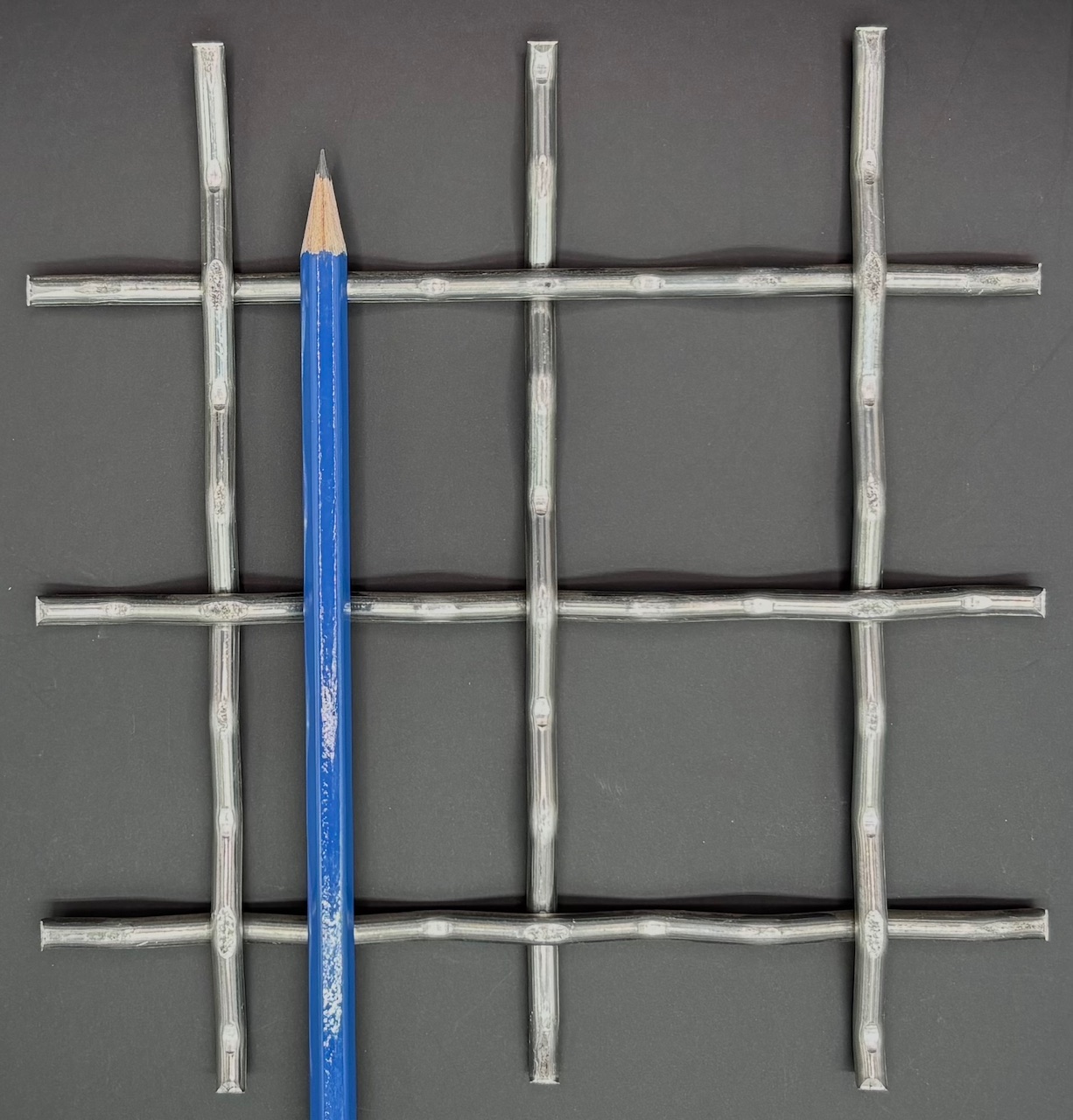

Product Code : ALWEA15I15I1875

Spec. Sheet

Centres or Mesh Count

1-1/2" x 1-1/2" (38.1 mm x 38.1 mm) c to cWire Diameter

0.1875" (4.76 mm)Clear Opening

1.313" (33.350 mm)Percent Open Area

76.60%Weight

TBD

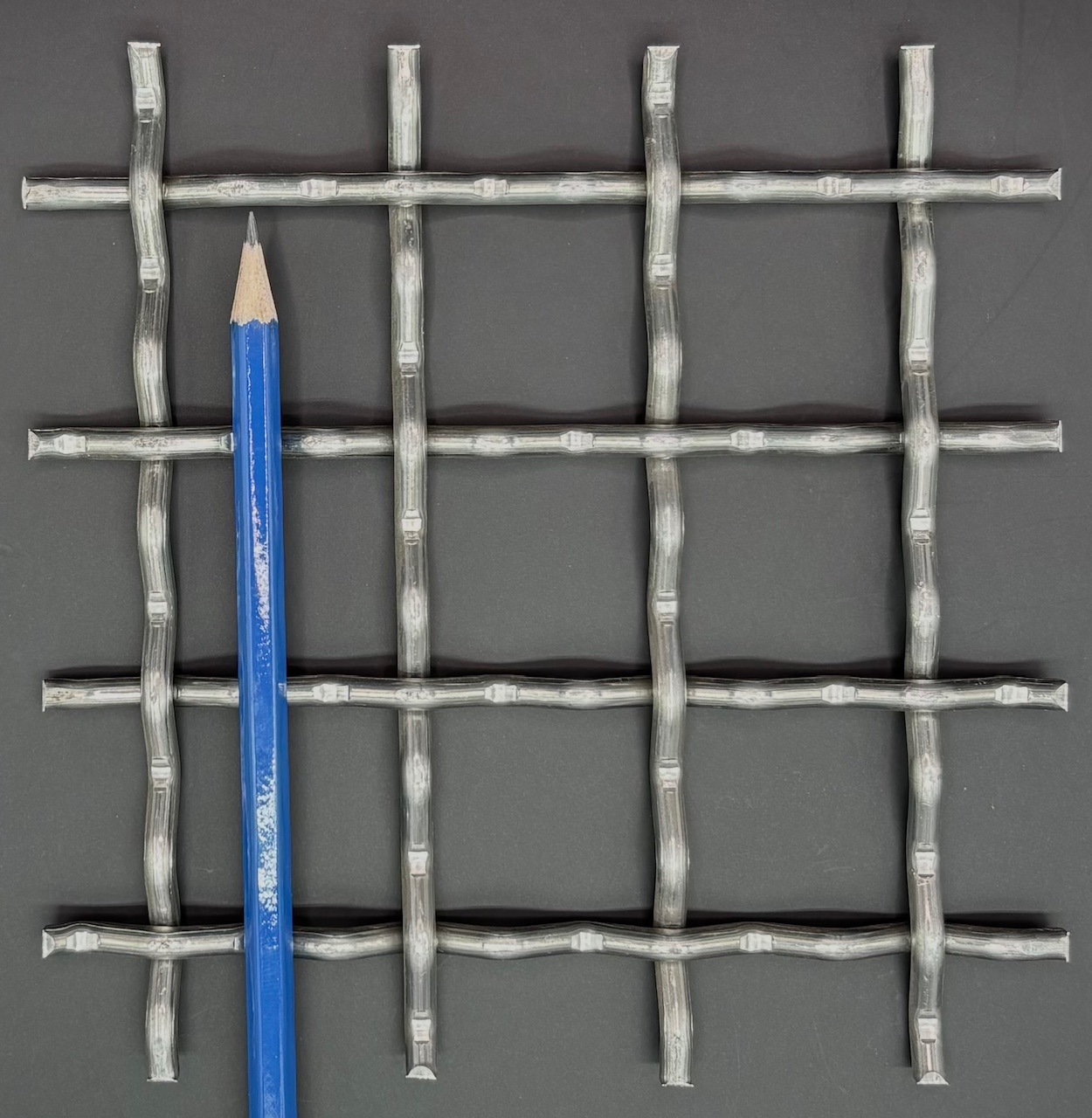

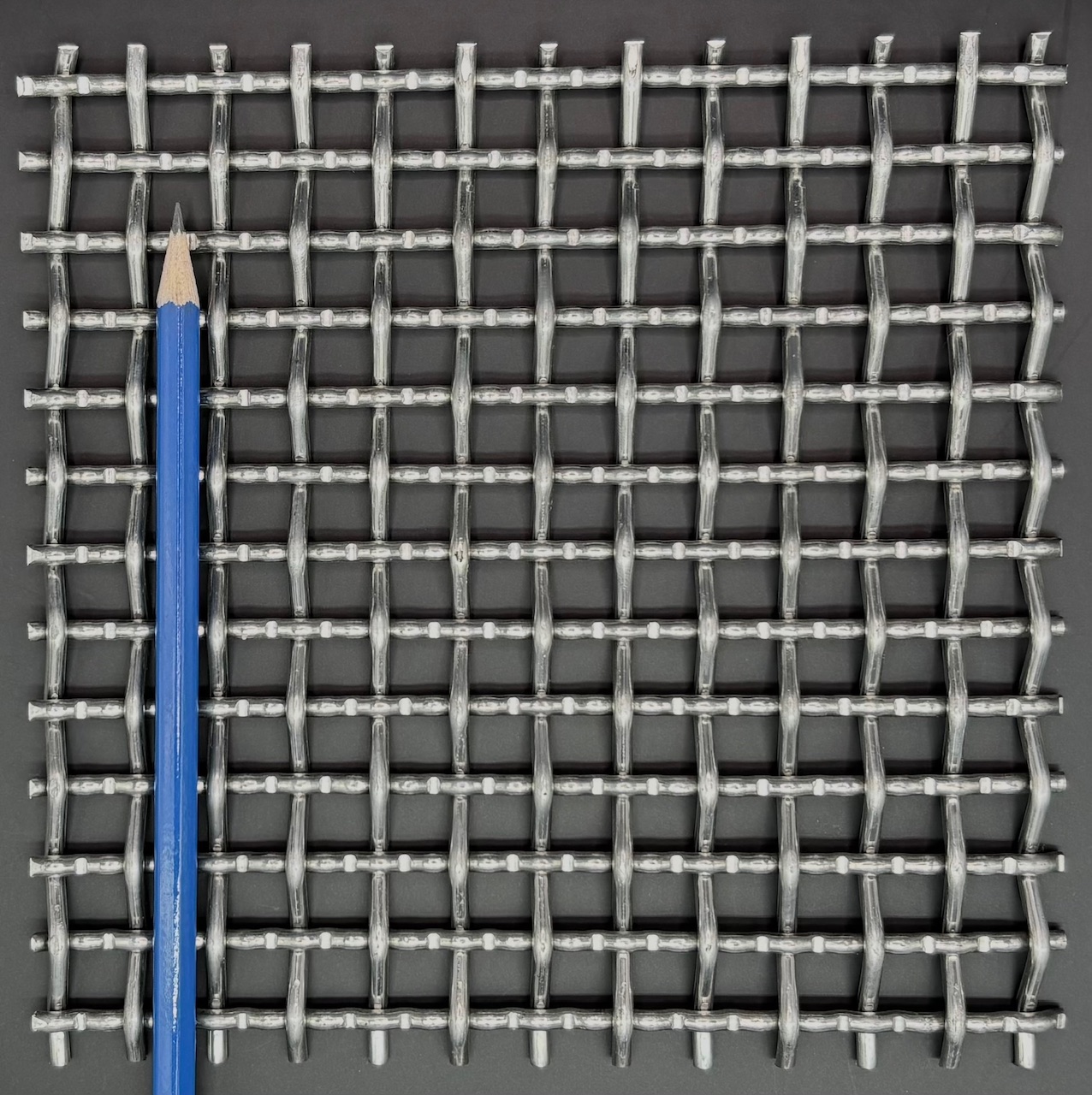

Product Code : ALWEA11125

Spec. Sheet

Centres or Mesh Count

1" x 1" (25.4 mm x 25.4 mm) c to cWire Diameter

0.125" (3.18 mm)Clear Opening

0.875" (22.23 mm)Percent Open Area

76.60%Weight

TBD

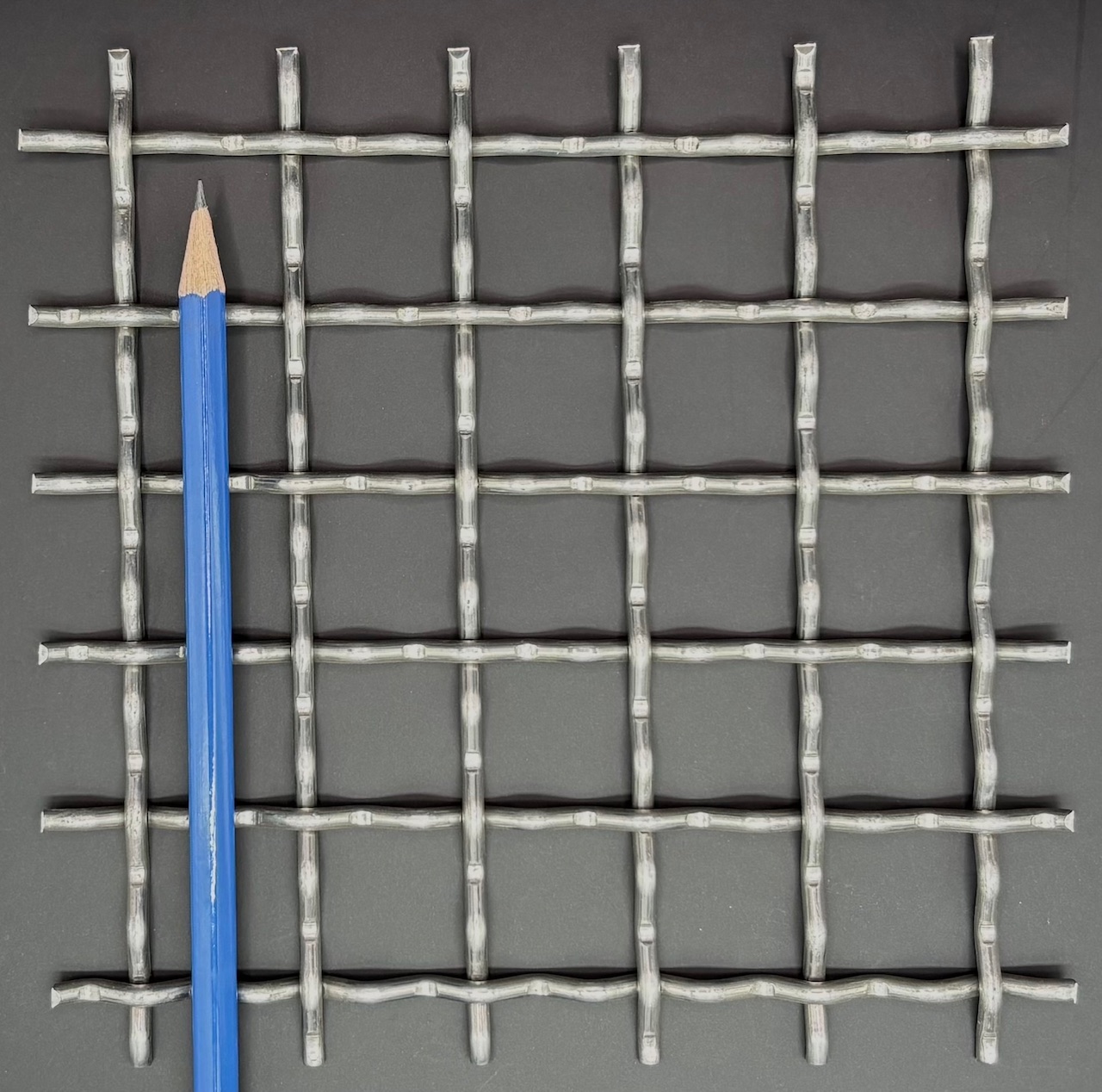

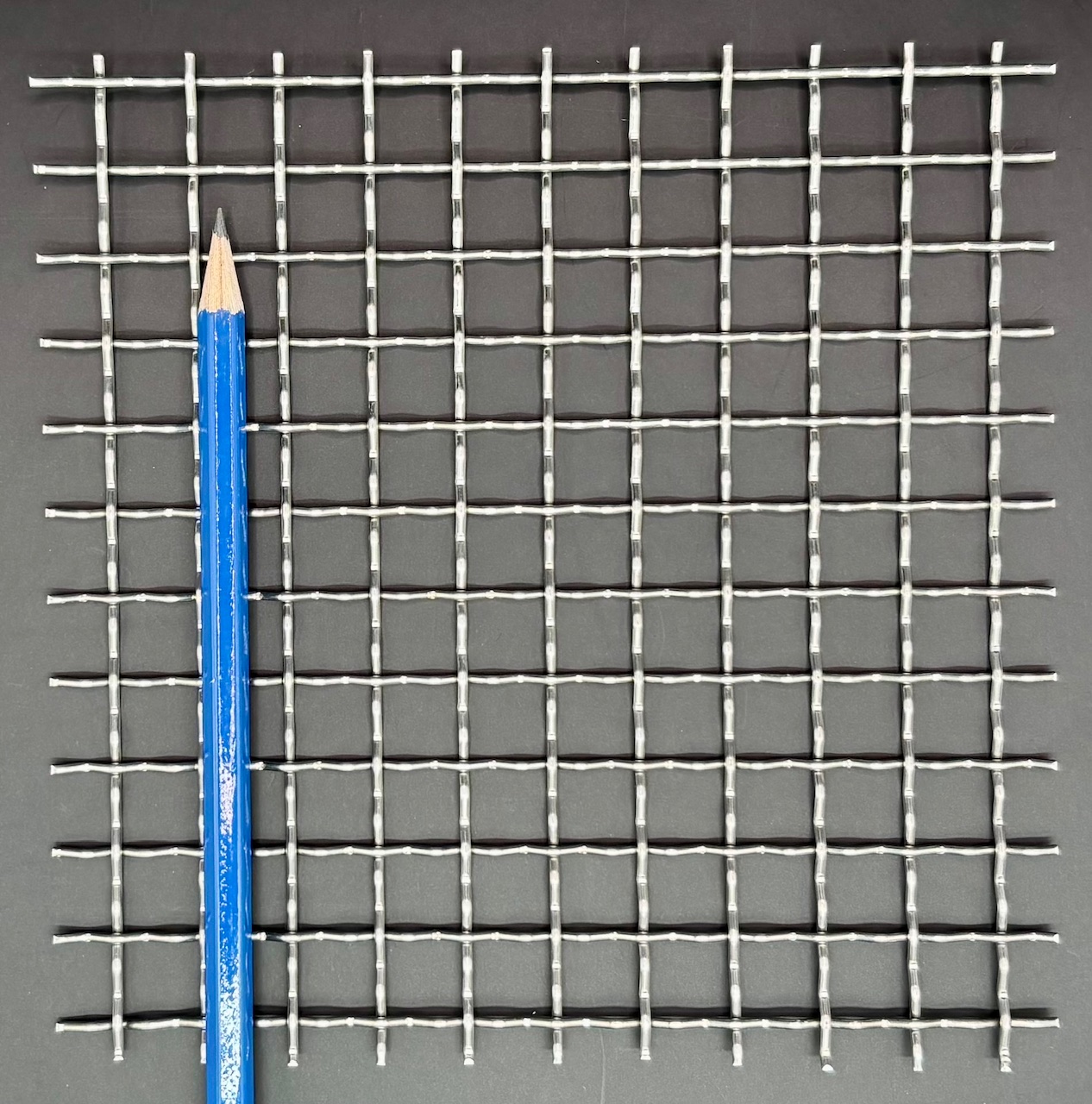

Product Code : ALWEA7575125

Spec. Sheet

Centres or Mesh Count

3/4" x 3/4" (19.1 mm x 19.1 mm) c to cWire Diameter

0.125" (3.18 mm)Clear Opening

0.625" (15.88 mm)Percent Open Area

69.40%Weight

TBD

Product Code : ALWEA22125

Spec. Sheet

Centres or Mesh Count

2 x 2 MESH 1/2" x 1/2" (12.7 mm x 12.7 mm) c to cWire Diameter

0.125" (3.18 mm)Clear Opening

0.375" (9.53 mm)Percent Open Area

56.30%Weight

TBD

Product Code : ALWEA22063

Spec. Sheet

Centres or Mesh Count

2 x 2 MESH 1/2" x 1/2" (12.7 mm x 12.7 mm) c to cWire Diameter

0.063" (1.60 mm)Clear Opening

0.437" (11.10 mm)Percent Open Area

76.40%Weight

TBD

Product Code : ALWEA44063

Spec. Sheet

Centres or Mesh Count

4 x 4 MESH (6.4 mm x 6.4 mm) c to cWire Diameter

0.063" (1.60 mm)Clear Opening

0.187" (4.75 mm)Percent Open Area

56.00%Weight

TBD

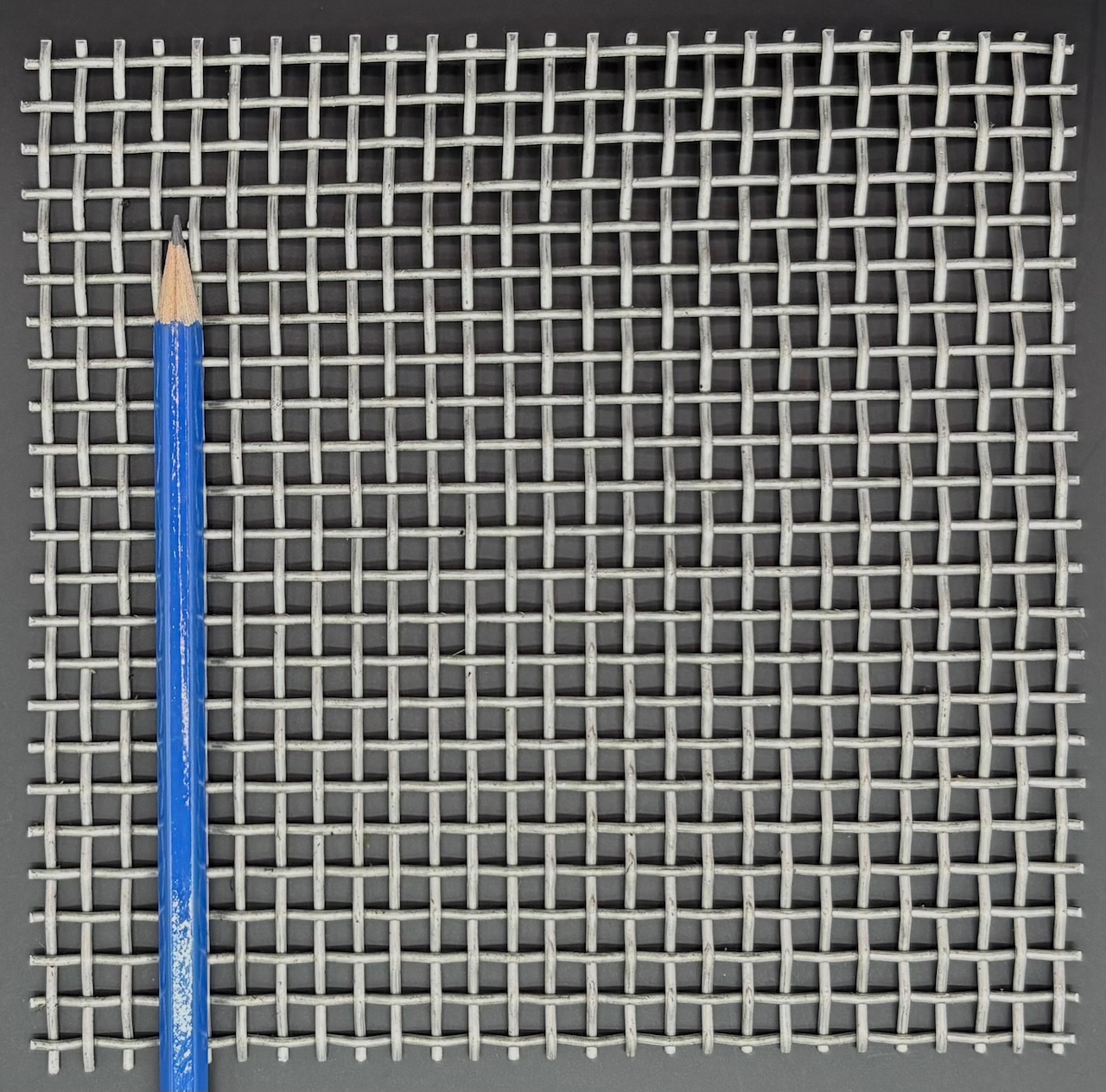

Product Code : ALWEA88028

Spec. Sheet

Centres or Mesh Count

8 x 8 MESH (3.2 mm x 3.2 mm) c to cWire Diameter

0.028" (0.71 mm)Clear Opening

0.097" (2.46 mm)Percent Open Area

60.20%Weight

TBDAluminum Weavemesh/Woven Wire Mesh Applications

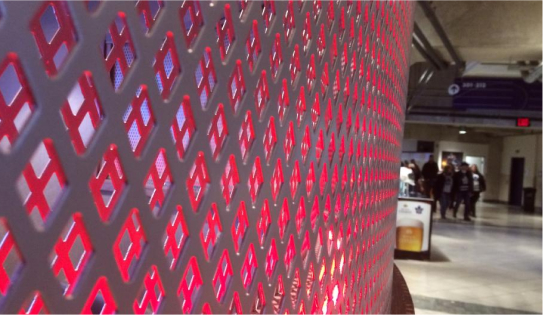

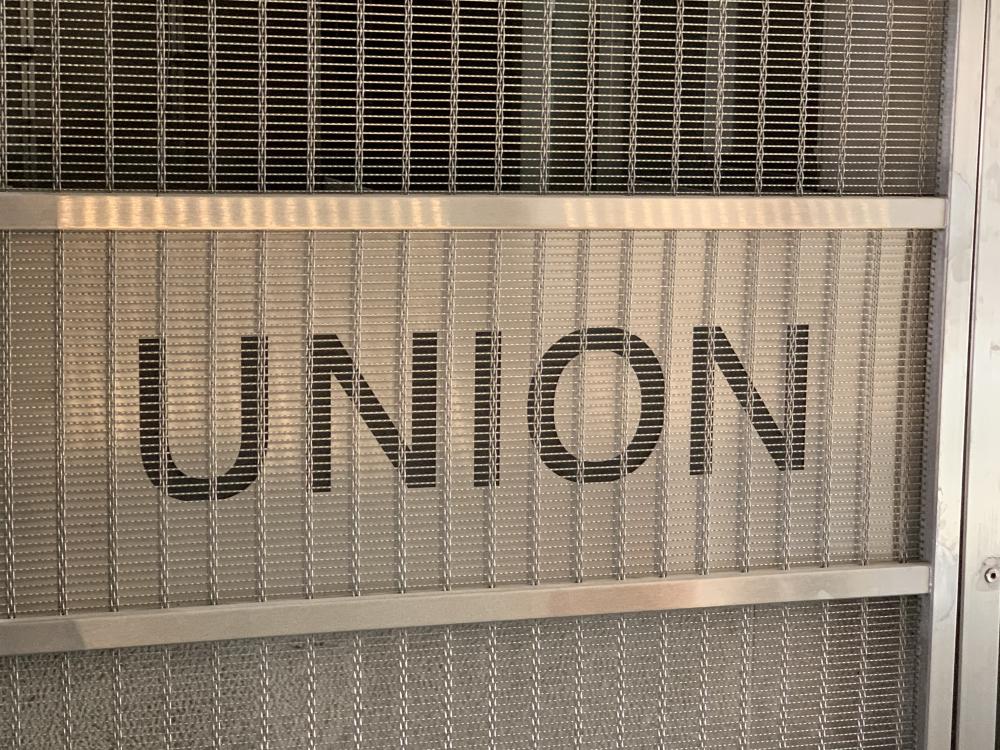

A common and one of the most popular applications for the heavier and larger (1/2” x 1/2” and coarser) aluminum weavemesh/woven wire mesh as lightweight guarding and railing infill panels. Its durability and cost-effectiveness make it an attractive alternative to powder-coated metal or stainless steel weavemesh. These patterns have also been used as backgrounds in signage onto which letters and graphics are then attached. The tighter of these patterns are suitable for use as privacy screens.

Aluminum curtain wall often incorporates the aluminum birdscreen (1/2” x 1/2" x 16 ga) to prevent birds, small animals, and debris from access. It is also used in aluminum HVAC applications for the same purpose.

We have custom woven the ¾” x ¾” pattern a number of times to be used as an attractive lightweight and cost-effective alternative to standard ceiling tile options. In one condominium project, the ceiling of the top floor hallway was a little lower than the other floors. The mesh was used to both restrict the view of the mechanical systems above it while still creating the feeling of height in the hallway.

The aluminum insect screen has a number of uses in construction. In addition to being installed as insect (window) screen it is also used as soffit screen. Industrially it is an economical and lightweight mesh to hold filter media in place.

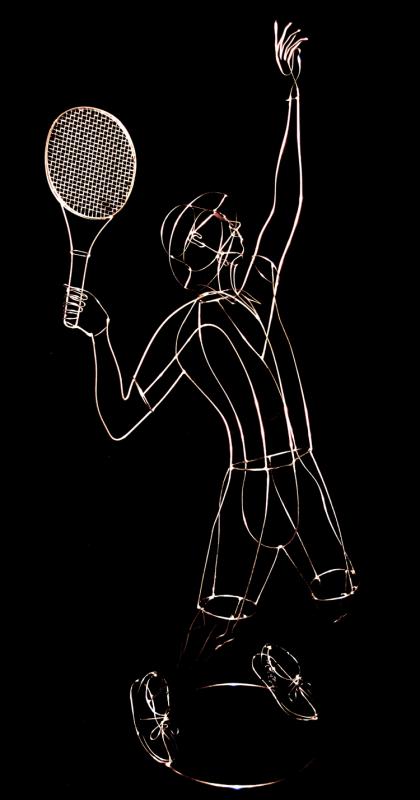

Finer aluminum mesh is easily formed and manipulated for sculpture and design projects. We have also seen it used for trade show booths and presentation stages hung from the ceiling as a screen onto which displays and media are projected.

Anodizing aluminum is an electromechanical process that converts the metal into a decorative, durable and corrosion-resistant finish. Please contact us if you have any questions about this process.

Why Choose Aluminum Weavemesh/Woven Wire Mesh?

Characteristics of Aluminum weavemesh/woven wire mesh:

- Lightweight

- Corrosion resistant

- More economical than stainless steel counterparts

- Long-lasting

- Anodizing finishing options that are very durable and long-lasting

- Custom size and pattern weaving options

If you have any questions about our aluminum weavemesh or any other products or projects, please email us or call us.