Wire mesh is a staple in multiple industries, depending on the material and its applications. For example, a stainless steel wire mesh finds extensive use in construction, oil refineries, food processing, and agriculture, making them a robust and versatile solution. However, many users might find it challenging to select the right wire mesh for a particular application, as the right specification needs to be determined for this purpose. In order to comprehend this specification, it’s crucial to learn some wire mesh-related terminology.

Major wire mesh definitions

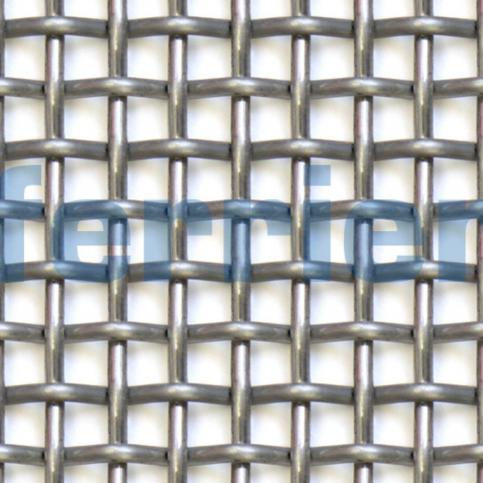

Mesh Count: It’s the distance between the midpoint of a single wire to a distance of 1 inch in any direction. In this manner, mesh count determines the number of holes or openings per inch.

Mesh Opening: The dimensions of the hole or opening is also a crucial factor while selecting a wire. This dimension is defined by mesh opening, which is the distance between two parallel single wires that are closest in proximity.

Wire Diameter: This is basically the diameter of a single round wire used in a mesh, also known as a gauge.

Filter Rating: Also known as Minimum Efficiency Reporting Values or MERV rating, this measure is used to determine the retention level of a wire mesh. Basically, it is defined as the size of a particle that it can filter or separate from the others, and is conveyed in microns.

Weave: The typical grid-like pattern created on a wire mesh is known as a weave. A mesh can be made in different types of weaves, such as a Plain Weave, Plain Dutch Weave, or Twill Weave.

Shute Wires: Wires that run across the width of a mesh are known as shute wires.

Warp Wires: Wires that run across the length of a mesh are known as warp wires.

Other parameters like types of weaves and the finish of a wire mesh will be discussed in a future blog.